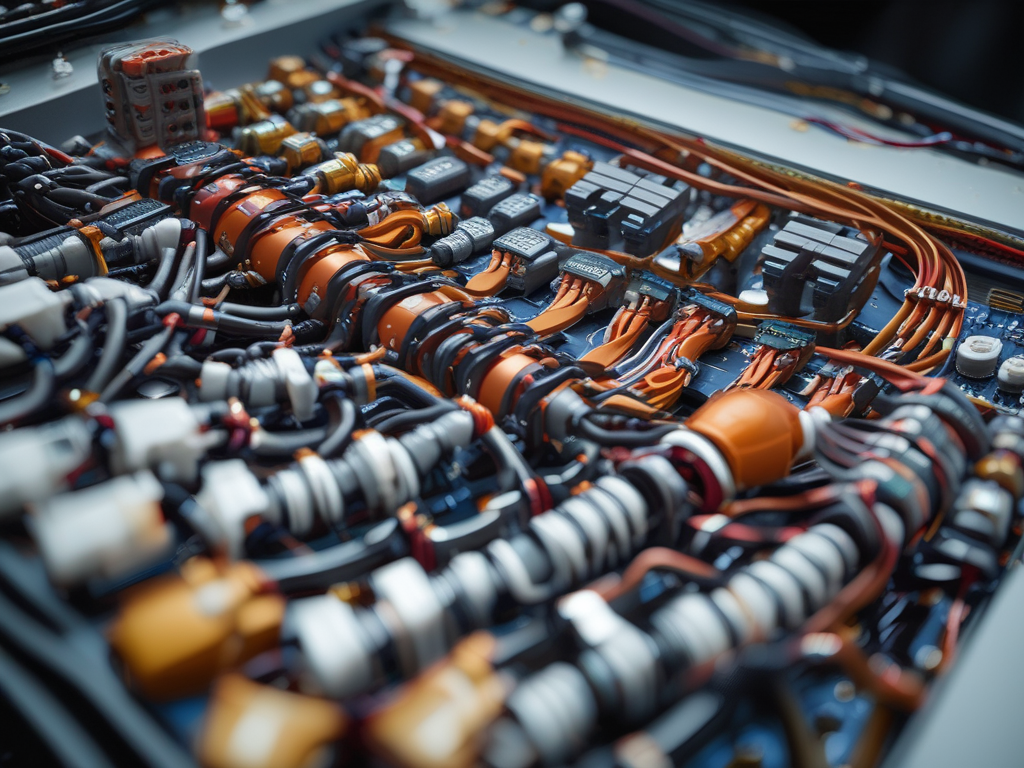

Designing reliable, high-quality electrical harnesses is critical for ensuring spacecraft and instrument performance in the harsh environments of space. Following industry-proven best practices for harness design can significantly reduce the risk of early mission failures.

At the forefront of these best practices is adhering to established standards like NASA’s Goddard Space Flight Center (GSFC) Design and Manufacturing Standard for Electrical Harnesses. This comprehensive standard outlines rigorous requirements spanning materials selection, fabrication techniques, testing, and contamination control.

Key Harness Design Best Practices:

- Wire and Cable Selection Wires and cables must be carefully chosen to withstand the extreme temperatures, radiation, and vacuum of space. The GSFC standard specifies approved wire sizes, insulation materials, and shielding based on electrical and environmental criteria.

- EMI Mitigation Techniques

Controlling electromagnetic interference (EMI) is vital. Proven methods include using separate harnesses for different signal types, grouping similar signals, shielding individual wires or wire bundles, and using twisted pairs and coaxial cables. - Physical Configuration Harness diameter, bend radii, wire breakouts, and cable routing paths are optimized for spatial constraints and installation requirements. Excess wire length accommodates future rework. Proper securing methods like lacing tape and cable clamps prevent excessive movement.

- Connector Best Practices Flight-approved connectors with protective covers and sealing grommets are selected. Torquing, staking with epoxy, matedermate cycle tracking, and periodic inspections ensure connector integrity.

- Contamination Control Rigorous cleaning during fabrication and after harness completion is mandatory. Solvents, ultrasonic cleaning, white/black light inspection, and certification processes eliminate contamination risks.

- Electrical Testing

Continuity checks against wiring diagrams, insulation resistance tests, and current/voltage drop analysis validate electrical performance before installation.

By implementing these space-proven design practices from conceptualization through manufacturing and testing, aerospace organizations can produce highly reliable flight harnesses. This mitigates potential points of failure and enhances the probability of successful, long-duration space missions.